💡 Introduction – Turning Vision Into Action

MemoDroid started as a bold idea:

Could I, as a single developer, design and build a fully functional robotic arm – complete with motion recording, Bluetooth control, a mobile interface, and smooth servo handling – in just a few weeks?

As a full-time computer science student balancing a packed academic semester and a demanding job, this wasn’t just a project. It was a test of focus, engineering, and willpower.

I took on this challenge as part of an IoT & Robotics course led by Dr. Yehuda Rosilho not knowing just how deep it would go. What followed was a true end-to-end engineering journey – every circuit, every line of code, every screw placed with intent and urgency.

📜 Goal & Core Idea

MemoDroid was designed to solve a real problem:

“Make it easy for anyone to automate small, repetitive tasks at home or work using a robotic arm.”

Key objectives:

- Remote control via mobile app

- Ability to record and replay movement routines

- Smooth, human-like servo transitions

- Intuitive UI for non-technical users

- Expandability (360° rotation, multiple profiles, scheduling)

But beyond the functionality, I wanted to design something accessible. MemoDroid isn’t just a robotic arm – it’s an approach to democratize robotics.

🧰 Planning & Architecture

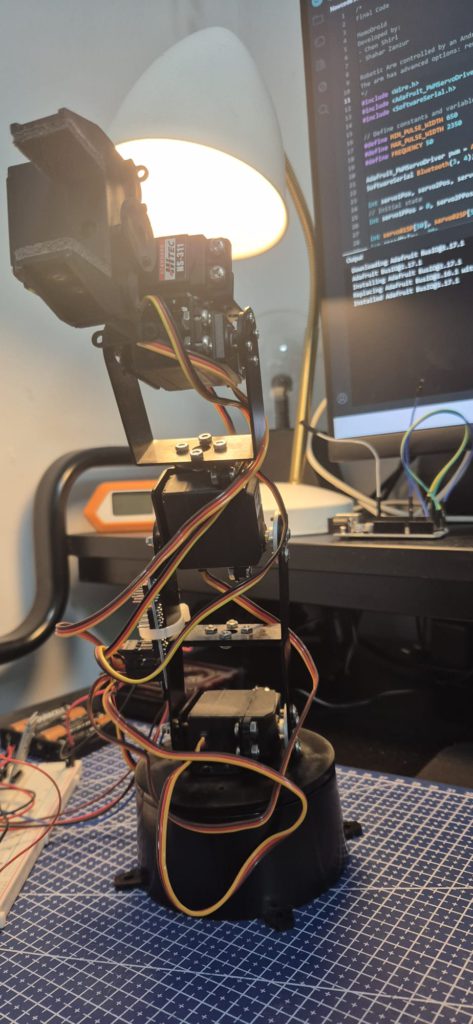

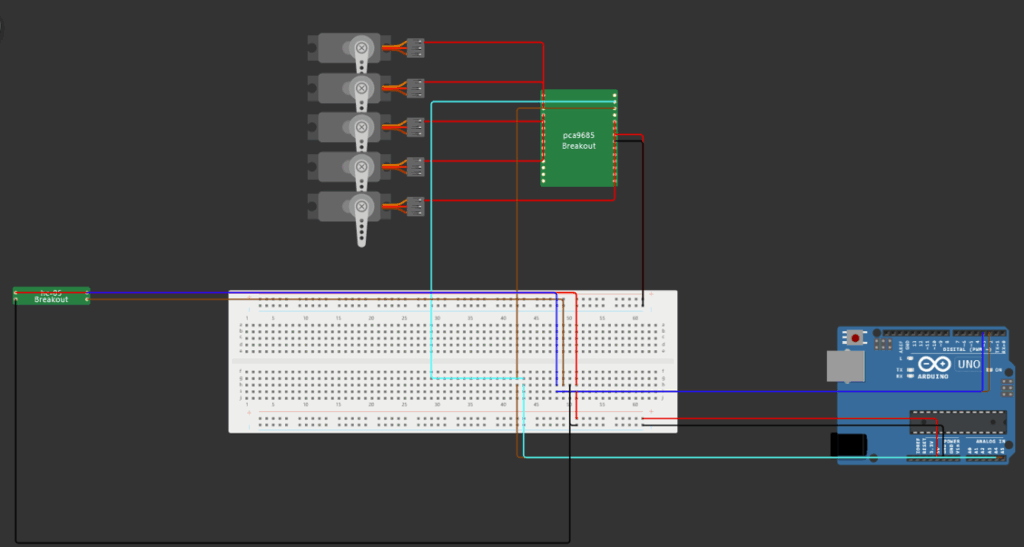

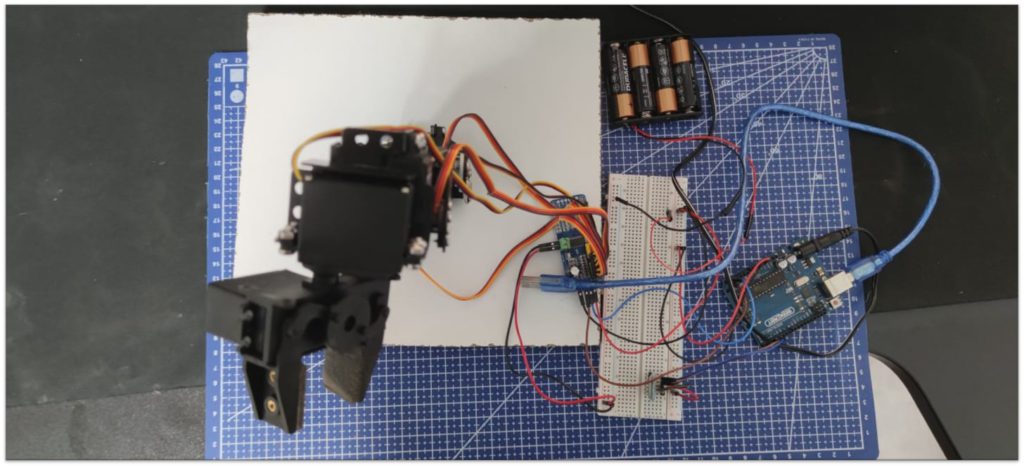

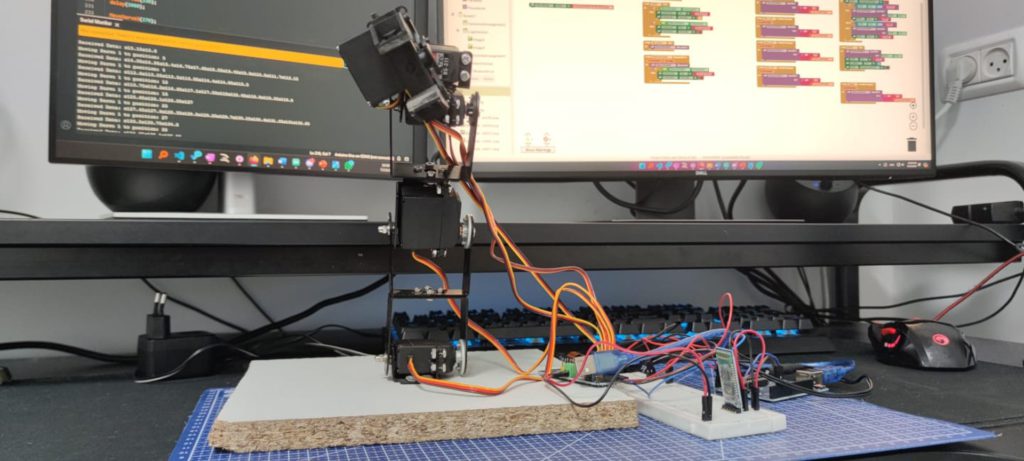

🔨 Hardware Stack

| Component | Description |

|---|---|

| Arduino Uno | Main microcontroller for servo control and logic |

| PCA9685 | 16-channel I²C PWM driver for precise motor control |

| 6 Servos Total | 5 standard + 1 continuous rotation |

| HC-05 Bluetooth Module | Wireless communication bridge with the mobile app |

| Breadboard + Jumpers | Prototyping and connection base |

| 6V 2A External Power | Dedicated supply to stabilize servo load |

➕ The Sixth Motor: 360° Servo

Halfway through the project, I added a 6th servo – the Hitec HSR-1425CR, a continuous rotation servo. Unlike the others, it doesn’t rely on angles – it uses PWM signal range to control speed and direction.

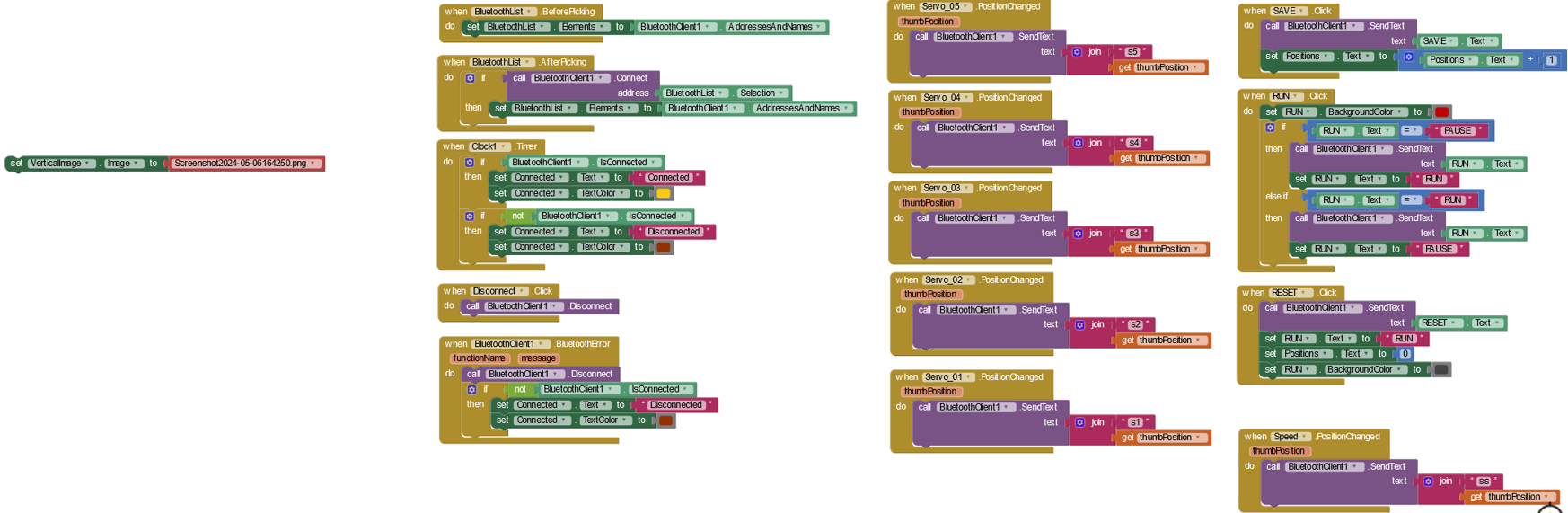

📲 Mobile Application

🛠️ Implemented Functionalities in the Arm and App

- 🎮 Manual Control for Each Servo

Real-time control via Bluetooth using commandss1tos6.

Supports both standard 180° servos and a continuous rotation servo (servo6). - 💾 Save & Replay Movement Routines

SAVE: Stores the current position of all servosRUN: Replays the saved sequence to automate tasks

- ⏱️ Custom Speed Control (Built from Scratch)

Speed control is not provided by default in servo movement.

I implemented a manual speed mechanism using delay injection between servo position updates.

The delay can be adjusted dynamically via thess<value>command to simulate different movement speeds. - 📡 Reliable Bluetooth Command Parsing

Developed a robust input buffer and parser to handle fragmented Bluetooth transmissions, ensuring commands are processed correctly even when split across multiple reads.

Supported commands include:RUN– Start executing saved routineSAVE– Save current positionsPAUSE– Temporarily stop executionRESET– Clear saved positions

Communication is done via custom serial protocol:

s1<angle>

s2<angle>

...

s6<mode> (1-5)

Each message is sent to the Arduino and interpreted by the core parser.

⚙️ Firmware & Control Logic

🌟 Command Handling

All servo commands are processed via handleCommand(), which intelligently reads commands like s2130 and moves the relevant motor.

For Servo 6:

s6<1–5> → mapped to:

1 = full reverse (0)

2 = slow reverse (45)

3 = stop (90)

4 = slow forward (135)

5 = full forward (180)

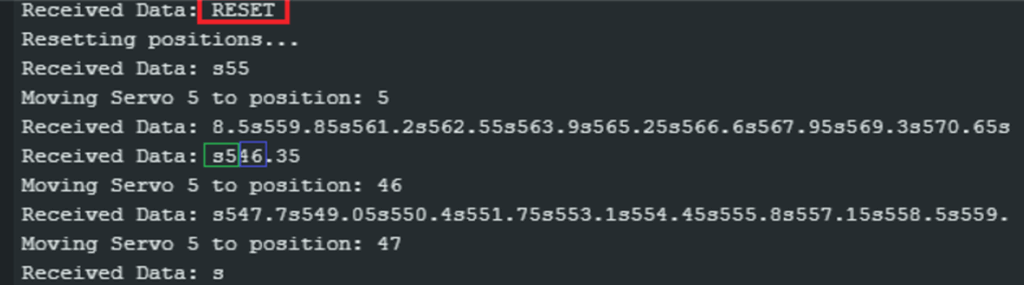

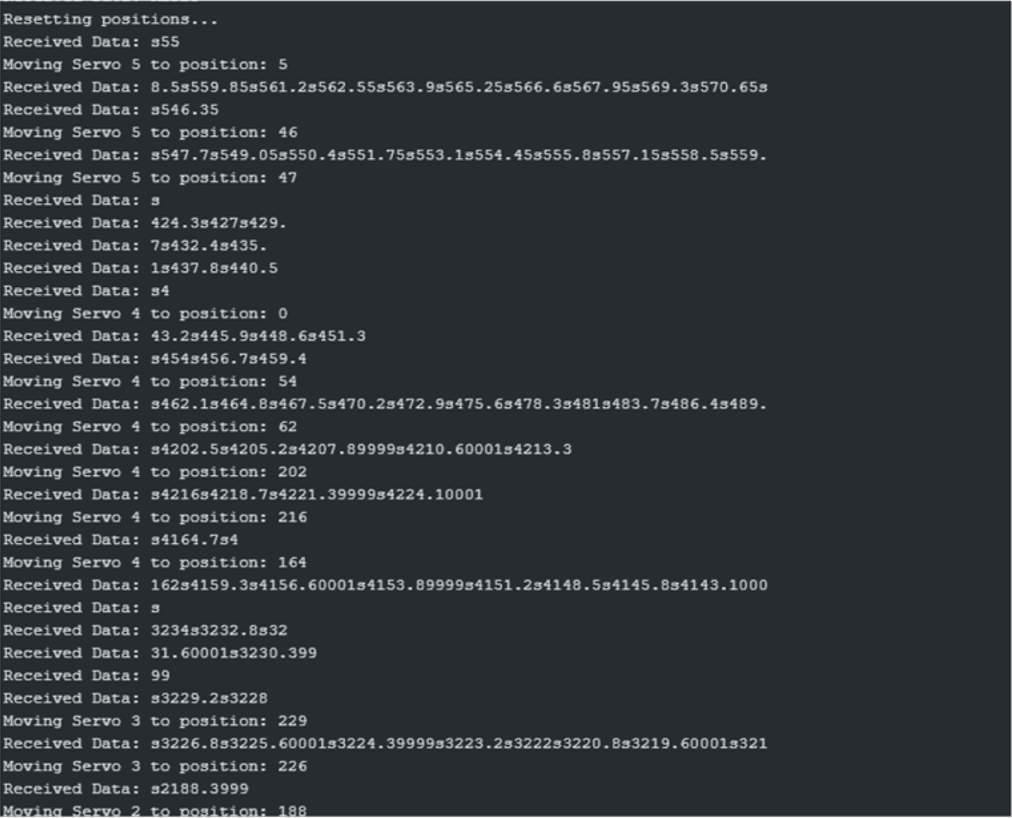

🧐 Buffered Bluetooth Parser

One of the hardest bugs I encountered was due to Bluetooth message fragmentation. Data arrived in pieces, like:

s3

1

80

This caused misfires and corrupted commands. To solve this:

- I built a custom string buffer

- Extracted complete commands using

indexOf('s') - Deferred processing until a full command was available

Now the robot reads fragmented Bluetooth messages perfectly every time.

🧪 Calibration & Testing

I implemented a TestCalibration() routine and spent hours adjusting and observing each servo to get ranges right:

- Servo 1: 0-45°

- Servo 2: 100-130°

- Servo 3: 150-270°

- Servo 4: 0-270°

- Servo 5: 45-180°

- Servo 6: 1-5 (mapped to continuous rotation behavior)

This fine-tuning ensured that MemoDroid behaves like a real robotic system, not a toy.

⚠️ Roadblocks I Overcame

| 🛡️ Obstacle | 🛠️ Solution |

|---|---|

| Motors jittering from insufficient power | Switched to 6V 2A external supply |

| No PCA9685 or HC-05 parts in simulator | Manually designed the full electronic scheme |

| Bluetooth messages broken mid-stream | Built a custom buffered parser |

| Complex calibration ranges | Developed test functions + manual tuning |

| Debugging during silent failures | Added real-time Serial Monitor logs |

✅ Results & Capabilities

- Built a functional robotic arm from scratch

- Added 360° motor support

- Built a mobile controller from scratch

- Implemented data recording and replay

- Created a stable custom communication protocol

- Made everything intuitive and modular

💻 Technical Architecture Snapshot

[Mobile App] → Bluetooth → HC-05 → Arduino Uno

↓

Command Parser & Logic Handler

↓

PWM via PCA9685 → Servo Motors (1–6)

🌐 Open Source

All firmware and design files are available here:

👉 GitHub: BlackD0C/RoboticArm

🌬️ What’s Next?

In future releases, I’d like to expand MemoDroid with:

- ☑️ Cloud scheduling + remote logging

- 🧠 Computer vision for object detection

- 🕹️ Joystick or gesture control

- 🌐 Web interface for control from any device

🧐 Reflections

MemoDroid was a passion project I brought to life from the ground up – writing the code, designing the circuits, building the app, and refining every detail.

This project taught me:

- That debugging hardware is 10x harder than software

- Why protocols and parsing matter

- And most importantly: with enough focus, you can do more than people expect – even alone

🙏 Final Thoughts

MemoDroid isn’t just a robot.

It’s a personal victory. A product of discipline, late nights, self-learning, and never giving up.

“You don’t need a team of engineers or unlimited time. Just a clear goal, smart planning, and the will to execute.”